| Lebitso la Sehlahiswa: | Magnet ea Neodymium, NdFeB Magnet | |

| Kereiti le Thempereichara ea Mosebetsi: | Kereiti | Mocheso oa Mosebetsi |

| N30-N55 | +80 ℃ / 176 ℉ | |

| N30M-N52M | +100 ℃ / 212 ℉ | |

| N30H-N52H | +120 ℃ / 248℉ | |

| N30SH-N50SH | +150 ℃ / 302 ℉ | |

| N25UH-N50UH | +180 ℃ / 356 ℉ | |

| N28EH-N48EH | +200 ℃ / 392 ℉ | |

| N28AH-N45AH | +220 ℃ / 428℉ | |

| Ho roala: | Ni, Zn, Au, Ag, Epoxy, Passivated, joalo-joalo. | |

| Kopo: | Li-sensor, li-motor, likoloi tsa sefa, li-magnetic holders, libuela-hōle, lijenereithara tsa moea, lisebelisoa tsa bongaka, joalo-joalo. | |

| Molemo: | Haeba setokong, sampole ea mahala 'me u fane ka eona ka letsatsi le le leng; Ha e felile, nako ea ho fana e tšoana le tlhahiso ea bongata | |

Neodymium Magnet Catalog

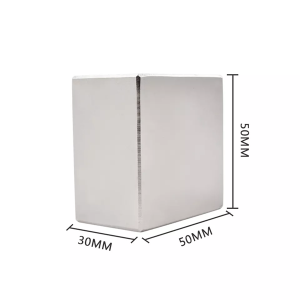

Rectangle, rod, counterbore, cube, shaped, disc, cylinder, ring, sphere, arc, trapezoid, joalo-joalo.

Letoto la makenete ea Neodymium

Mohala oa makenete oa neodymium

NdFeB square counterbore

Disc neodymium makenete

Arc shape neodymium makenete

NdFeB ring counterbore

Makenete ea rectangular neodymium

Thibela neodymium makenete

Cylinder neodymium makenete

Tataiso ea magnetization ea makenete e khethoa nakong ea ts'ebetso ea ho etsa. Tataiso ea magnetization ea sehlahisoa se felileng e ke ke ea fetoloa. Ka kopo, etsa bonnete ba hore u hlakisa ntlha e lakatsehang ea magnetization ea sehlahisoa.

Ho roala le ho roala

Liaparo tse tloaelehileng tsa limatlase tsa NdFeB ke life?

NdFeB matla a makenete barbotage ka kakaretso nickel, zinki, epoxy resin joalo-joalo. Ho itšetlehile ka electroplating, 'mala oa sebaka sa makenete o tla boela o fapane,' me nako ea polokelo e tla boela e fapane ka nako e telele.

Litlamorao tsa NI, ZN, epoxy resin, le li-coatings tsa PARYLENE-C holim'a thepa ea makenete ea limatlase tsa NdFeB litharollong tse tharo li ile tsa ithutoa ka papiso. Liphetho li bonts'itse hore: tikolohong ea asiti, alkali, le letsoai, ho koaheloa ha lintho tsa polymer Tšireletso ea makenete ke eona e ntle ka ho fetisisa, resin ea epoxy e batla e fokola, ho roala ha NI ke ea bobeli, 'me seaparo sa ZN se batla se fokola.

Zinc: Bokaholimo bo shebahala bo le bosoeu bo bosoeu, bo ka sebelisoa bakeng sa lihora tse 12-48 tsa setlolo sa letsoai, se ka sebelisoa bakeng sa sekhomaretsi se itseng, (joalo ka sekhomaretsi sa AB) se ka bolokoa lilemo tse peli ho isa ho tse hlano haeba se entsoe ka electroplated.

Nickel: e shebahala joaloka tšepe e sa hloekang, bokaholimo bo thata ho ba oxidized moeeng, 'me ponahalo e ntle, gloss e ntle,' me electroplating e ka fetisa tlhahlobo ea spray ea letsoai ka lihora tse 12-72. Bothata ba eona ke hore e ke ke ea sebelisoa bakeng sa ho kopanya le sekhomaretsi se seng, se tla etsa hore seaparo se oele. Potlakisa oxidation, hona joale mokhoa oa electroplating oa nickel-copper-nickel o sebelisoa haholo 'marakeng bakeng sa lihora tse 120-200 tsa sesepa sa letsoai.

Phallo ea Tlhahiso

Ho paka

Lintlha tsa ho paka: liphutheloana tse kentsoeng ka matla a makenete, mabokose a foam, mabokose a masoeu le lishiti tsa tšepe, tse ka bapalang karolo ea ho sireletsa magnetism nakong ea lipalangoang.

Ha ho tluoa tabeng ea ho tsamaisa thepa e nang le maikutlo a matla a makenete, ho bohlokoa ho nka mehato ea ho netefatsa hore lihlahisoa li sirelelitsoe tšitiso efe kapa efe ea makenete. Sena ha se boloke lihlahisoa tse bolokehileng feela empa hape se tiisa boleng ba tsona.

Lintlha tsa thomello: Nakong ea matsatsi a 7-30 kamora netefatso ea odara.

LBH

Ikutloe u lokolohile ho ikopanya le rona!

Re thabela ho fana ka kamohelo e mofuthu ho bareki bohle ba rona le balekane ba nang le thahasello ea ho hlahloba khoebo ea rona ea tlhahiso. Ka lilemo tse fetang 20 tsa boiphihlelo, re motlotlo ka ho fana ka lihlahisoa tsa boleng bo holimo tse fetang tebello ea bareki ba rona.

Re na le sehlopha sa litsebi tse netefatsang hore lits'ebetso tsa rona tsa tlhahiso li tsamaellana le litekanyetso le melaoana ea indasteri. Mehaho ea rona ea tlhahiso e na le lisebelisoa tsa theknoloji le lisebelisoa tsa morao-rao tse re nolofalletsang ho fana ka tharollo e sebetsang le e sebetsang ho bareki ba rona.

Qetellong, re moetsi ea tsebahalang ea nang le tlaleho e netefalitsoeng ea katleho indastering. Re u amohela ho re etela le ho latsoa boitlamo ba rona ba ho sebetsa hantle ka bo uena. Re leboha ha o re nka re le molekane oa hau oa tlhahiso, 'me re labalabela ho etsa khoebo le uena.